- M2 rolled threads – smoother, stronger and more durable than CNC cut threads.

- End type available with hex/torx socket, slotted, and cross recessed.

- Made from Gr5 (ti6al4v) solid titanium bar, fully inspected by supersonic detection.

- Available also in GR1, GR2, GR9 etc. titanium grades.

- Customizable threads (metric or inch) and lengths.

- Anodizing & PVD coatings optional.

- Available materials are: aluminum, stainless, copper, copper alloy, brass, zirconium, molybdenum, tungsten etc.

Materials of Allen Key M2 Titanium Set Screws

The following grades of materials are optional as regular stocked materials. If required material grade is not listed, please let us known.

In this table, the composition and strength of the materials are listed.

| Titanium Grades | Composition | Density | Tensile | Yield | |||

| GBT | ASTM | gram/cm3 | MPa | KSI | MPa | KSI | |

| TA1 | GR1 | Pure Titanium | 4.51 | 240 | 35 | 138 | 20 |

| TA2 | GR2 | Pure Titanium | 4.51 | 345 | 50 | 275 | 40 |

| TC4 | GR5 | Ti6Al4V | 4.43 | 895 | 130 | 828 | 120 |

| GR9 | Ti3Al2.5V | 4.48 | 620 | 90 | 483 | 70 | |

Compared to other commonly used metals, Allen Key M2 Titanium Set Screws are easy to make, light and corrosion resistant, yet it does not require surface treatment in most circumstances.

The following table also shows the comparison of titanium alloy, stainless steel and aluminum alloy that are used for machinery parts and industrial fasteners like bolts/screws, nuts and washers etc.

| Material | Property | Density | Tensile | Yield | Typical Application |

| Typical Grade | gram/cm3 | Mpa | Mpa | ||

| Titanium Alloy | Gr5 (Ti6Al4V) | 4.43 | 895 | 828 | Aviation |

| 304 Stainless Steel | 304(08Cr19Ni9) | 7.93 | 515 | 205 | Kitchen Utensils |

| Aluminum Alloy | 7075 | 2.81 | 560 | 495 | Aviation |

Materials We Deal with

Most common materials (including their alloys) we deal with are: titanium, aluminum, copper, stainless steel, tungsten, zirconium, molybdenum.

Thread Sizes

Threads of the Allen Key M2 Titanium Set Screws can be made in metric, BS, and UN series. Thread pitches and diameters follow the major standards of ISO/BS/ASME specifications.

Major Processes of Making Allen Key M2 Titanium Set Screws

- Purchase of solid titanium bars/rods.

- Supersonic inspection and mechanical tests of titanium bars/rods.

- Continuous CNC machining of the basic profile of the Allen Key M2 Titanium Set Screws from the bars/rods.

- Threading

- Tapping threads.

- CNC cutting threads.

- Rolling threads.

- Inspection of the Allen Key M2 Titanium Set Screws.

- Cleaning, washing, drying & packing of the Allen Key M2 Titanium Set Screws.

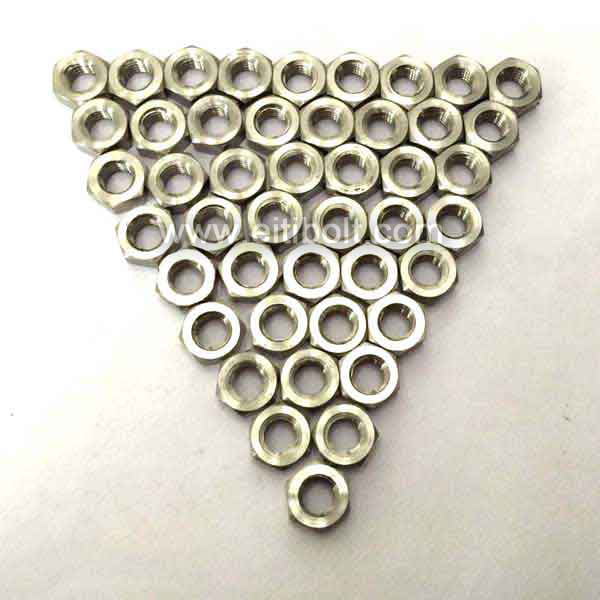

Packing of Allen Key M2 Titanium Set Screws

The titanium nuts and fittings are mostly packed in plastic bags and shipped in carton boxes.

Shipping

We use the world famous couriers like FedEx, TNT, UPS, DHL etc. to delivery our titanium bolts/screws, nuts/fittings, washers and other fasteners to our global clients.

Manufacturing Capabilities

We have the skills and equipement to bring your ideas/designs into real, physical titanium parts/fasteners.

- CNC turning/shaving/milling/grinding of titanium parts and fasteners.

- Casting/forging/wire EDM cutting of titanium parts profiles.

- High precision threading of titanium parts and fasteners.

- Rolling and CNC cutting of metric/inch threads of titanium parts and fasteners.

- PVD coating of titanium parts and fasteners.

- Anodizing of titanium parts and fasteners.

- MAO of titanium parts and fasteners.